Product Description

Are you still working in dirty and wet construction site, moving many heavy machines to the site? Are you still waiting for more than half a year before you can move inside to your new house? Are you still paying high salary to the workers and still unhappy about the final work?

You are so lucky to be here and get to know the best substitute to traditional concrete wall, it is called light weight EPS sandwich panel. Comparison with other wall materials, this one is more stronger and longer life span with many advantages and wide usages.

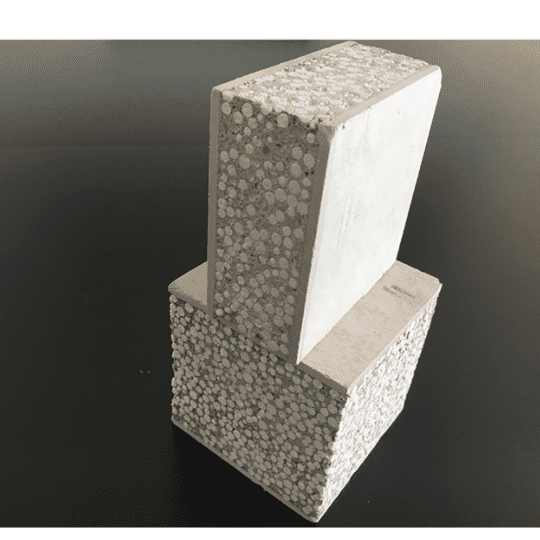

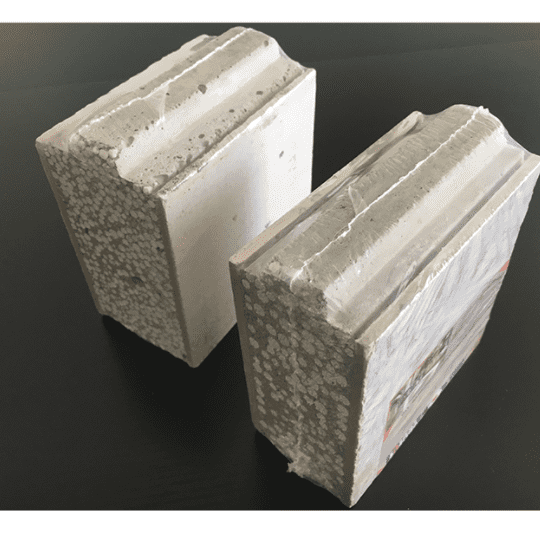

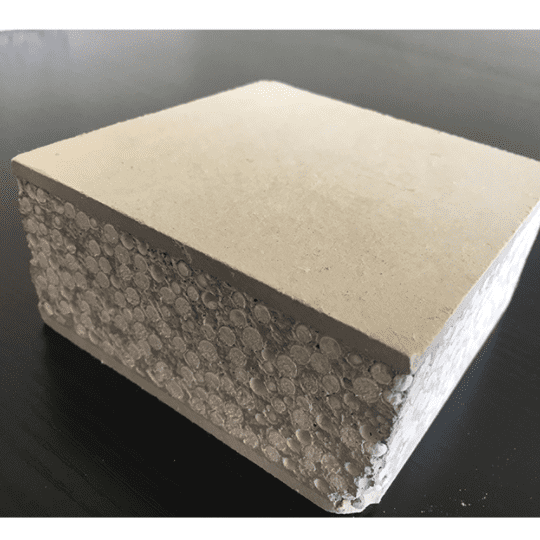

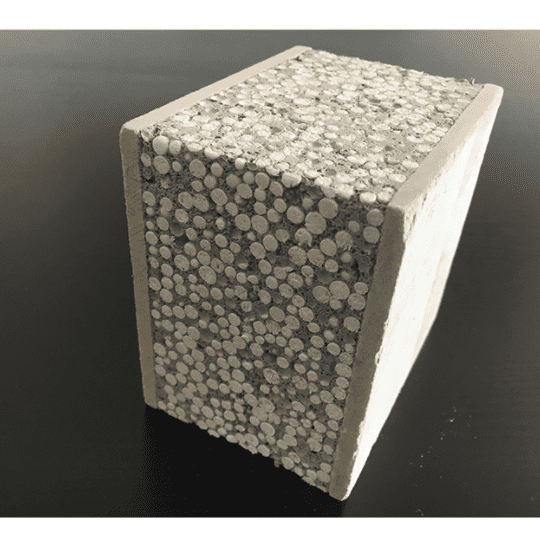

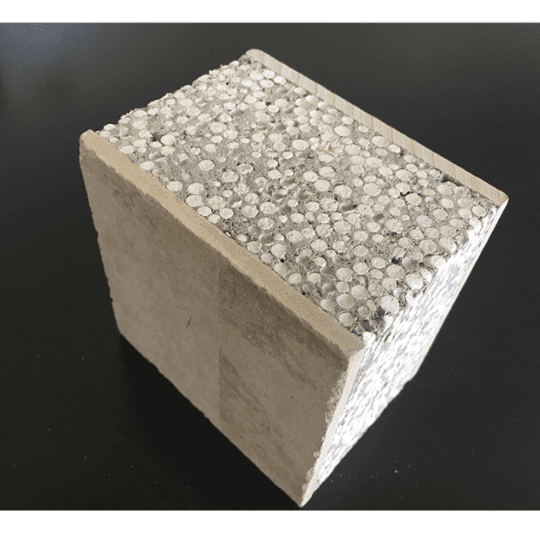

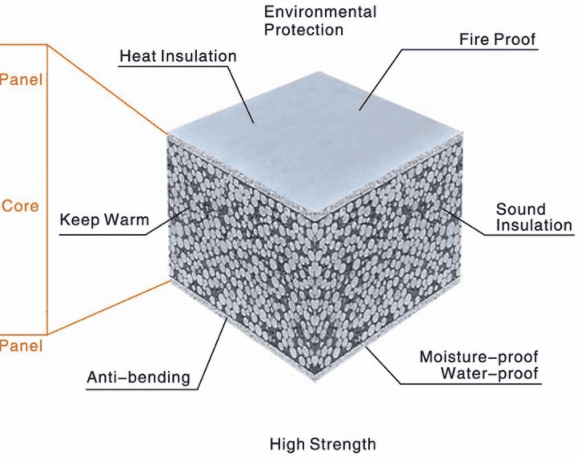

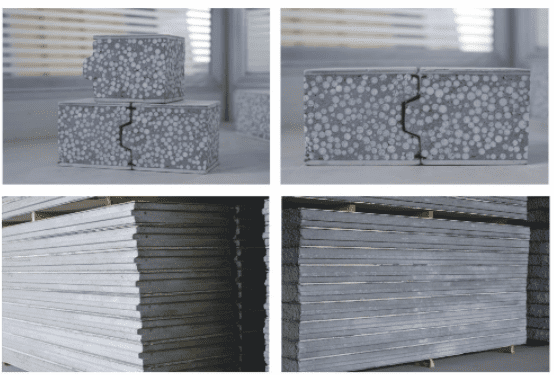

TRUSUS EPS (Expanded polystyrene board) wall Panel is composed of exterior panels and interior core filling, to form a non-load-bearing light-weight composite wall panel. The exterior panels on both sides are 5mm calcium silicate board, and the middle core is filled with polystyrene beads & cement or ceramsite, polystyrene beads & cement.

Types

1) Light weight EPS sandwich panel(with face board and without face board)

2) Ceramiste sandwich wall panel (with face board and without face board)

3) Perlite sandwich wall panel (with face board and without face board)

Main Features

1) Energy-saving, li

ghtweight, and environmental protection

2) Plystyrene granule in Vanjoin board has good heat-insulation effect and heat lost ratio is far below the other brick wall building

3) Energy-saving effects of the building is greatly improved

4) Raw materials do not include harmful substances

5) Environmental products, it is highly recommended by the government

6) Capacity: 650kg/m3, just one sixth of the brick building

7) Comparison of inner wall panel 75 and 120mm it will increase 12m practical area, for 100m2 house, it will increase 4.16m2

8) Waterproof and damp resistant

9) With fireproof feature

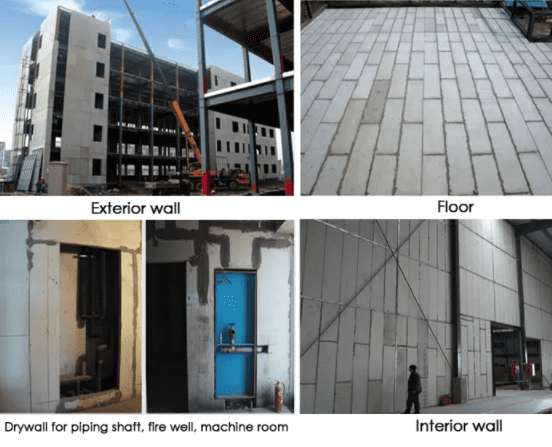

Application

Interior wall, exterior wall,roof and floor on steel or concrete structure. For various buildings, additions or renovations.

SHIPPING TIME: 7-20 working days after receiving your advance payment, some specifications are in stock

9. Buried conduit

Buried conduit inner wall, the switch socket box,the installation of water depending on design requirements disposable unit shown in the wallboard all strong, weak, and all kinds of water supply and drainage ducts line, box, cartridge position, not at the same at the same time slot position on both sides of the opening hole, and the conservation of the wall should be carried out after a minimum of three days. In cases where the same position on both sides of the wall while the wiring pipe, casing, switch boxes, should be shifted in a horizontal direction or a height direction of 100mm or more, so as not to reduce the sound insulation wall. When the slot, the width should be good to play the slot size, and with a (small) cut out border Portable cutting machine, and then the artificial light gouges, rigorous violence slotted openings, generally not more than the depth of gouges wall thickness 2/3 of the width of not more than 400mm. Embedding mode and Line Pipe Specification perform the requirements, to the level of the conduit should not exceed 350mm, polymer cement mortar stratified slab according to backfill the processing line handling the well pipe burial.

10. A joint (crack tape joining) process

Process should be conducted after the seam doors,window frames, pipe installation (not less than 7 days). First clean the seam area, fill up the pore damaged, clean surface, and then paste the seams crack with construction, and follow these steps:

1, should remove dust attached to the front surface of the joint with crack;

2, the maintenance and the like grout slurry was completely dry, with more than 50mm wide crack fiber mesh tape stuck on the white latex paste slit, and compacted with a scraper along the seams, scrape excess white latex;

3, fiber mesh Once dry, then more than 100mm wide crack fiber mesh or perforated paper with white tape attached to stick to the slit latex, and compacted with a scraper along the seams, scrape excess white latex and removing bubbles taken off the grid;

4, the mesh belt after the other joints (punched tape) completely dry, can be according to design requirements (e.g. plaster) of the wall construction of the surface finish.

Chuweidi Technology (Beijing) Co., Ltd.

- Phone: +86 010-13683643193

- Business Type: Trading Company

- Location: China

- Main Products: Gypsum Board, PVC Gypsum Ceiling Tiles, Fiber Cement Board, Ceiling T-Grid, Steel Channel

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: