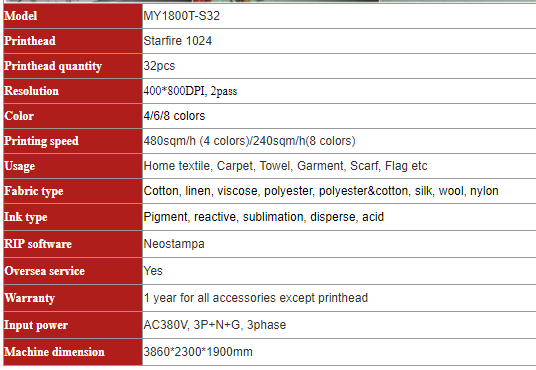

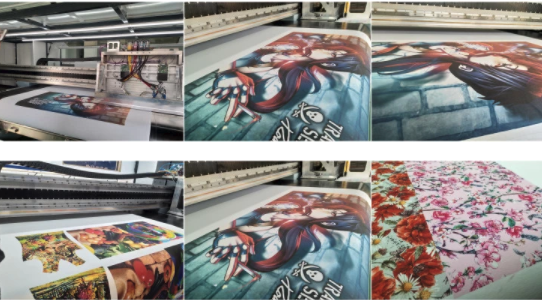

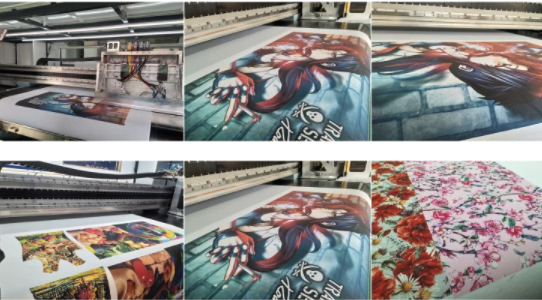

Starfire 1024 Sublimation Ink Direct Printing to Fabric Printing High Speed Towel Fabric Printing Machine

Product Description

Starfire 1024 Sublimation Ink Direct Printing to Fabric Printing High Speed Towel Fabric Printing Machine

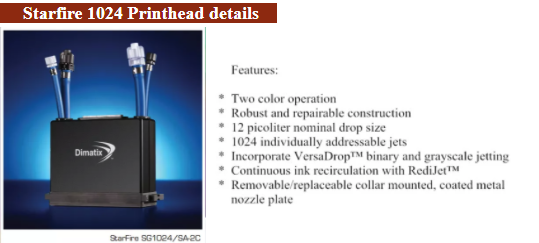

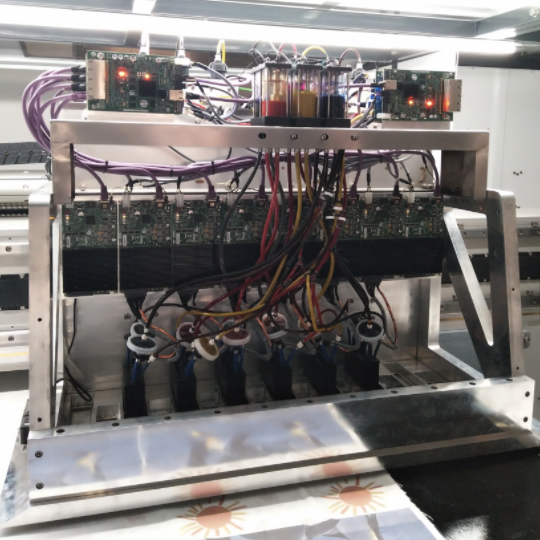

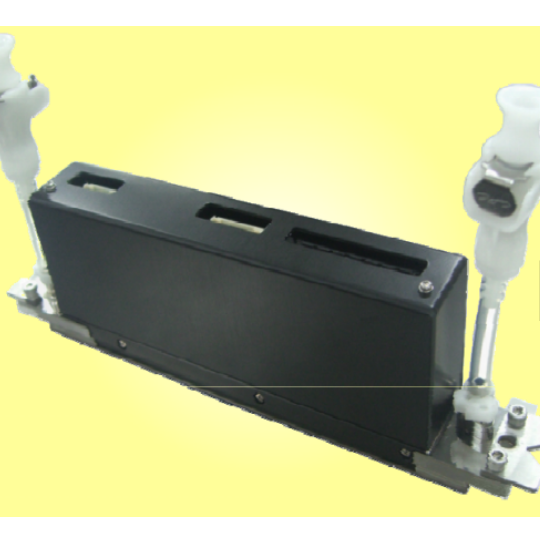

The StarFire SG1024/SA-2C printhead is a breakout inkjet innovation for high performance printing and decorative applications. It is purpose-built for today’s demanding high-speed scanning and single-pass industrial systems designs. It is an easy to integrate, high performance, drop-on-demand printhead for two-color operation at resolutions up to 200 dpi.

A robust and repairable construction makes it ideal for Textile, Wide Format and Commercial

Printing and Decorating.

Combining superior jetting performance with a high nozzle packing density in a compact, self-contained unit, the StarFire SG1024/SA-2C uses field proven materials to deliver a long service life with consistent and reliable output. Each SG1024/SA-2C printhead has two separate ink paths each

with 512 independent channels arranged in 4 rows in a single nozzle plate for resolutions up to 200 dpi. All 1024 nozzles can be fired simultaneously or individually. Equipped with a singular, durable, collar mounted, coated metal nozzle plate to withstand abrasion and resist damage, it is removable for cleaning or replacement. The printhead has a nominal 12 picoliter drop size with jetting fluids in the 8 to 20 centipoise range. When combined with VersaDrop™ jetting technology, the SG1024/SA-2C can produce drop sizes up to33 picoliters and full grayscale without penalty to productivity.

The StarFire SG1024/SA-2C is compatible with solvent, UV-curable, and aqueous based inks and maintenance fluids. Using RediJet™ technology, the SG1024/SA-2C continuously recirculates inks through the printhead at the nozzle and refill chamber to increase open time, reduce downtime and improve startup, especially for highly pigmented and fast drying inks.

RediJet allows StarFire printheads to be quickly and easily primed with minimal ink waste thereby increasing the inherent productive capacity of the printing system by reducing maintenance times and associated costs.

The StarFire SG1024/SA-2C printhead has simplified interfaces. The electrical interface consists of one 60-pin

The StarFire SG1024/SA-2C printhead is a breakout inkjet innovation for high performance printing and decorative applications. It is purpose-built for today’s demanding high-speed scanning and single-pass industrial systems designs. It is an easy to integrate, high performance, drop-on-demand printhead for two-color operation at resolutions up to 200 dpi.

A robust and repairable construction makes it ideal for Textile, Wide Format and Commercial

Printing and Decorating.

Combining superior jetting performance with a high nozzle packing density in a compact, self-contained unit, the StarFire SG1024/SA-2C uses field proven materials to deliver a long service life with consistent and reliable output. Each SG1024/SA-2C printhead has two separate ink paths each

with 512 independent channels arranged in 4 rows in a single nozzle plate for resolutions up to 200 dpi. All 1024 nozzles can be fired simultaneously or individually. Equipped with a singular, durable, collar mounted, coated metal nozzle plate to withstand abrasion and resist damage, it is removable for cleaning or replacement. The printhead has a nominal 12 picoliter drop size with jetting fluids in the 8 to 20 centipoise range. When combined with VersaDrop™ jetting technology, the SG1024/SA-2C can produce drop sizes up to33 picoliters and full grayscale without penalty to productivity.

The StarFire SG1024/SA-2C is compatible with solvent, UV-curable, and aqueous based inks and maintenance fluids. Using RediJet™ technology, the SG1024/SA-2C continuously recirculates inks through the printhead at the nozzle and refill chamber to increase open time, reduce downtime and improve startup, especially for highly pigmented and fast drying inks.

RediJet allows StarFire printheads to be quickly and easily primed with minimal ink waste thereby increasing the inherent productive capacity of the printing system by reducing maintenance times and associated costs.

The StarFire SG1024/SA-2C printhead has simplified interfaces. The electrical interface consists of one 60-pin

How to choose suitable ink in suitable processes for your own fabric:

1, For Cotton, linen, viscose fabric

A.Reactive ink: Pre-treatment(Padding)+Printing+Steaming+Washing+Sizing.

2, For Cotton, linen, viscose, cotton&polyester

A.Pigment ink: Pre-treatment(Padding)+Printing+Drying

3, For Polyester fabric

A. Disperse ink: Pre-treatment(Padding)+Printing+Steaming+Washing+Sizing.

4, For Silk, Wool fabric

A. Reactive ink/Acid ink:Pre-treatment(Padding)+Printing+Steaming+Washing+Sizing.

5, For Nylon fabric

A. Acid ink: Pre-treatment(Padding)+Printing+Steaming+Washing+Sizing.

Recommended

-

High Speed Digital Textile Printing Machine for Cotton Fabric and ClothUSD 220000.00

High Speed Digital Textile Printing Machine for Cotton Fabric and ClothUSD 220000.00 -

Home textile printing machine with DX5 printheadUSD 105000.00

Home textile printing machine with DX5 printheadUSD 105000.00 -

Mingyang industrial digital textile fabric printing machineUSD 1250000.00

Mingyang industrial digital textile fabric printing machineUSD 1250000.00 -

Starfire 1024 Sublimation Ink Direct Printing to Fabric Printing High Speed Towel Fabric Printing MachineUSD 1350000.00

Starfire 1024 Sublimation Ink Direct Printing to Fabric Printing High Speed Towel Fabric Printing MachineUSD 1350000.00 -

Kyocera KJ4B PrintheadUSD 7000.00

Kyocera KJ4B PrintheadUSD 7000.00