1. Product Information

§ Equipment use

The production lines are the most advanced ones in the aluminum industry of China, which has been obtained the most patents and exclusively-owned technologies. Adopting continuous cast-rolling technology, it is best for producing aluminum plate and strip.

§ Equipment composition

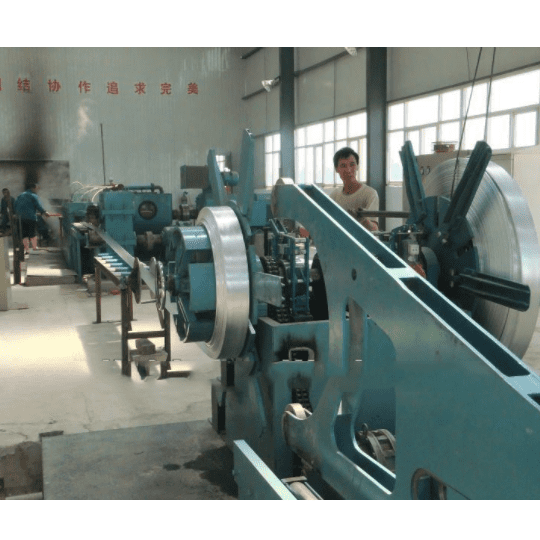

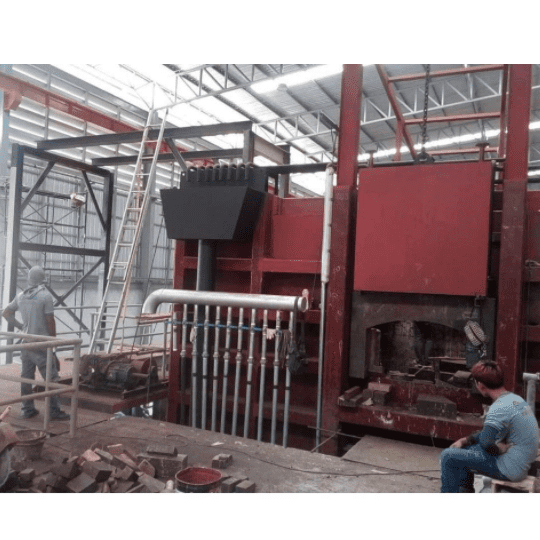

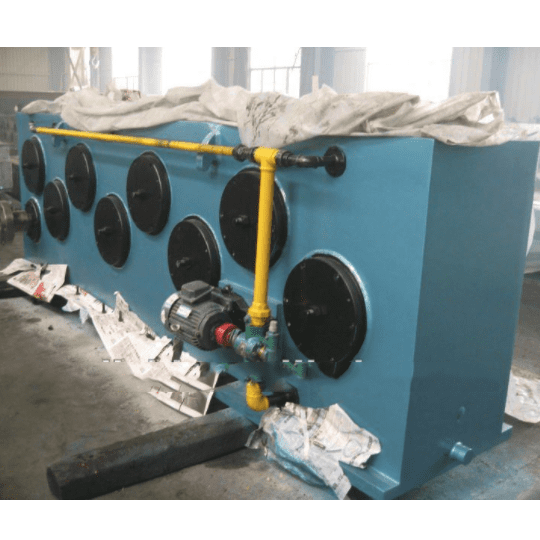

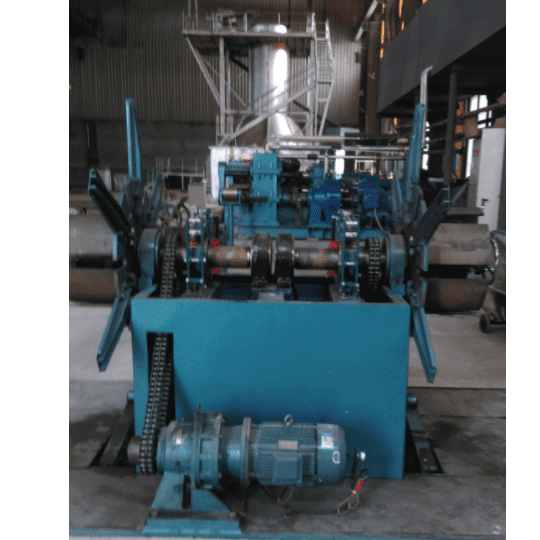

1.The aluminum strip continuous casting and rolling line is composed of casting machine, rolling shear, 4-stands rolling mill, double winder, electric control system, etc.

2. Molten aluminum or prepared aluminum melts flows from the holding furnace via the launder into casting machine,where it is continuously casted into ingots. Then fed into the rolling mill and rolled into plate and strip, finally laid down in winder.

§ Technical Data

Casting Machine | Crystallized wheels diameter | Φ1580mm |

Section surface of casting ingot | 2600mm2 | |

Driven motor | 4kw | |

Type of casting machine | 4-wheel | |

Rolling Shear | Shearing length | 720mm |

Motor power | 15 kw | |

Rolling Mill | No. of rolling stand | 4 |

Outlet strip thickness | 8~4mm | |

Outlet strip width | 150~100 mm | |

Production capacity | 5.8t/h | |

Finish rolling speed | 0.5m/s | |

Rolling center height | 910mm | |

Main motor | Z4-225-31 750 r/min 75kw | |

Double Winder | Max. winding weight | 660 kg |

Max. winding diameter | ø1550mm | |

Winding driven motor power | 4kw |