Multifunctional domestic wheat flour mill rice planting machine in india

Product Description

Brief Description

1.Flour milling machine model FMFQ is a big production milling equipment.It is usually used in large flour production line.

2.It capacity is 10 tons to 60 tons per day

3.It is not a complete processing line.So, need to configure other equipments.It usually used in 50 tons to 300 tons processing factory.

Technology

This series has the following distinctive characteristics:

1. The feeding is completed automatically in the simplest way, which significantly free workers from high workload while flour milling is nonstop.

2. Pneumatic conveying reduces dust pollution and improves the environment.

3. The ground stock temperature is reduced, while flour quality is improved.

4. Easy to operate and maintain.

5. It works for maize milling, wheat milling and cereal grain milling by change the different sieve cloths of flour extractor.

6. It can produce high quality flour by separate the hulls.

7. New design roll feeding guarantee a better free flowing of material.

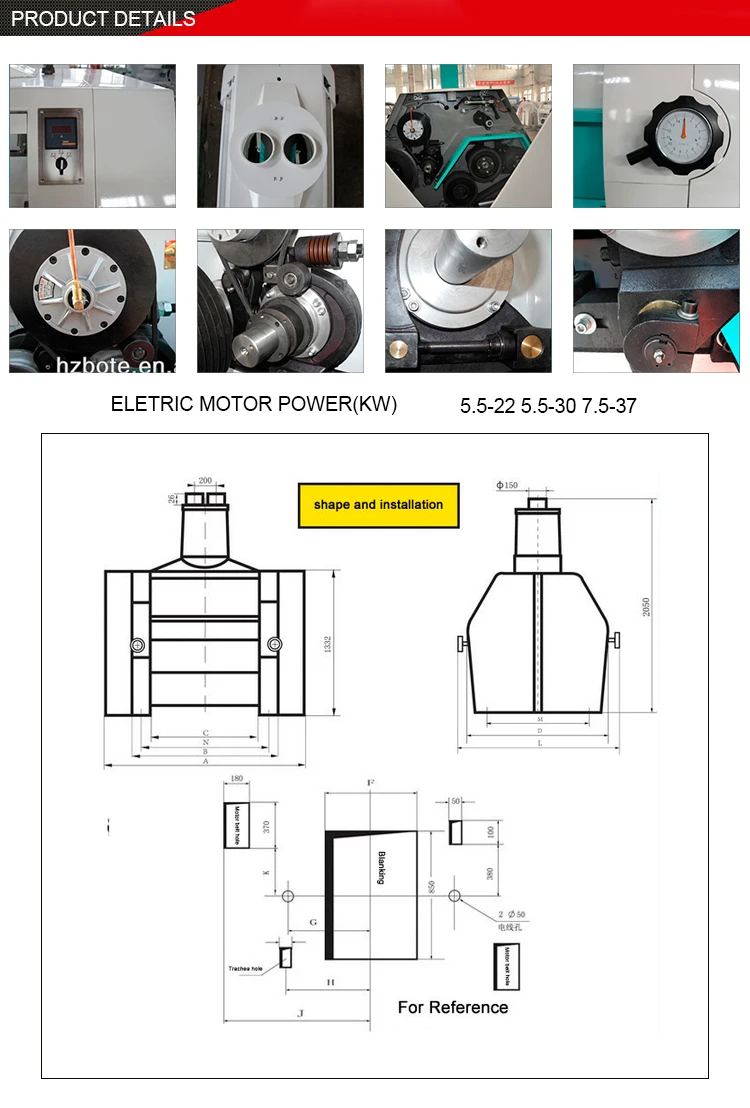

NO. Model Output(T/D) Weight(KG) Power(Kw) Outside(mm) 1 FMFQ 250-500 20 2000 5.5 1450*1330*1300 2 FMFQ 250-600 30 2400 5.5 1450*1330*1400 3 FMFQ 250-800 40 2800 7.5 1450*1330*1600 4 FMFQ 250-1000 50 3100 7.5 1450*1330*1850 5 FMFQ 250-1250 60 3450 7.5 1450*1330*2050 Item Model: FMFQ 250-500,600,800,1000,1250 Roller's Diameter/Enth (mm) 250/500, 250/600, 250/800, 250/1000, 250/1250 Fast Milers Speed (r/min) 300-500 Speed Ratio Fast Roller To Slow Roller (mm) 1:2.5, 1:2, 1:1.25 Raw Material Cozing Roller's Diameter (mm) φ75 Rotation Speed Of Rw Material Clozing Roller's (Mpa) 30-660

Features

Features

1. The lower half of the machine uses the high-strength cast iron, the upper part is made of high quality steel by laser cutting carbon

dioxide protection welding, with good stability, good cushioning effect.

2. Pneumatic pressure automatic control, pulse signal. Unique hanging servo feeding mechanism. The stroke valve imports U.S. Parker products,

so it has a high sensitivity, the unit can achieve centralized control.

3. Achieving the best grinding effect with cylinder feeding tube of acrylic high transparent Plexiglass.

4. Roller through strict quality inspection and the dynamic balance treatment, no vibration, low noise, smooth operation.

5. Roller bearings with Swedish SKF, and installed Swedish special butter, low noise, long service life.

6. The parts surface of flour milling machine adopts the pure manganese black phosphate treatment, covers a protective film so that it is bright and not fade.

7. The painting of mechanical housing surface uses the automotive paint, so that the whole is delicate and beautiful.

Accessories

1.We choose the top Accessories to make sure the machine is strong and durable.

2.Our core components adopt premium brands and materials to extend the use of machines

Application

This series of products has been widely used in large wheat, corn, maize,soybean, oats, barley, hummus, etc. automatically processing line.

1. wheat storage →→→ (silos, or warehouse)

2. Cleaning system →→→ (sifter, destoner, separator, magnet, scourer, etc)

3. Dampening →→→ (dampener, conditioning silos, etc)

4. Milling system →→→ (roller mill, plan sifter, purifier, impact detacher, etc.)

5. Flour pressure and blending system →→→ (if need)

6. Flour packing and stacking →→→ (automatic packing machine,stacking machine)

Hanzhong Burt Machinery Co., Ltd.

- Phone: +86 0916-2315201

- Business Type: Manufacturer

- Location: China

- Main Products: Grain Flour Milling Machine,Grain Flour Processing Line,Grain Dryer

- Total Employees:100-500 people

- Year Established:

- Export Markets:

- Total Annual Revenue: