High quality CO2 supercritical oil fluid bilberry extract

Product Description:

Supercritical Fluid Drying is a new drying technology, compared with the traditional drying methods such as spray drying, freeze drying, vacuum drying, the use of supercritical fluid has strong dissolving ability, dissolve and replacement of the material being dry, namely through pressure and temperature control, make the solvent reached its critical point in the drying process, complete supercritical of liquid to gas phase shift, resulting in dry products.

Solvent is ethanol, acetone, etc., the characteristics of supercritical fluid drying process is the use of supercritical fluid zero surface tension, a component in the supercritical state with solid - liquid interface disappeared, acceleration of gas-liquid, gas-solid mass transfer, heat transfer and decrease the interfacial tension of common drying process to the destruction of the structure of solid particles, cause the dry material in the drying process is not appear due to capillary tension affect the microstructure change, such as common tunnel collapse in freeze drying and spray drying for dry powder products adopt thermal destruction, supercritical drying and spray drying directly get powder products, and the particle size is generally spray drying powder products.

In addition, the transformation of the wet gel to aerogel can be completed under the premise of maintaining the gel skeleton structure, and the high quality aerogels are prepared, as well as some other nano-porous materials.

Product Parameters:

FEATURE & SPECIFICATION

1. The working pressure of the supercritical drying equipment is about 25MPa, the working temperature reaches 260, and the volume has reached 1000L (then can reach 3000L).

2. Equipment has simple structure, lighter weight, reliable sealing, kettle lid open and remove automated (without the other lifting equipment), the open kettle is quick and deft, greatly saves the open kettle time (only a few minutes), increasing the service efficiency of the equipment.

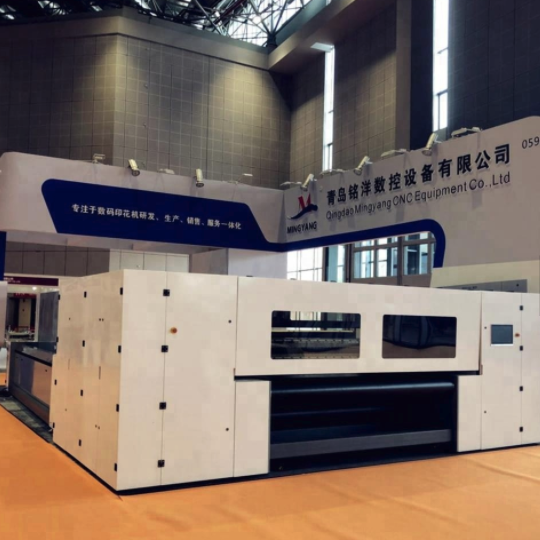

Product Display:

Advantages:

In the early 1990s, the company was committed to the research and development and design of supercritical extraction equipment, and constantly improved and improved, gradually forming its own equipment characteristics.

1.The extractor is equipped with a quick opening, the quick opening mechanism adopts special design (the technology introduced from US), and the switch kettle is portable and fast.

2. The extractor and separator are made of stainless steel integral forgings with high strength and long life.

3. Unique cylinder design, which increases the effective contact with the material in the extractor, overcomes the "bypass" phenomenon of CO2, improves the extraction efficiency and yield, and reduces the extraction time.

4. The heat exchange system is equipped with electric heating device. The temperature can be set arbitrarily and the heating is stable and uniform.

5. Adopt the refrigeration unit of joint venture technology, the refrigeration effect is good, the appearance is beautiful.

6. Equipment has reliable security: in addition to the pressure device has enough safety margin, the extractor, separator, evaporator are equipped with safety relief valve, and CO2 pump discharge has pressure limited protection, the whole units will stop running while over pressure.

7. Control system operation is simple: extraction and separation pressure, heating and cooling temperature, CO2 flow can be determined by process.Computer centralized control, 17 inches color LCD touch screen display and control, high speed, high performance microprocessor, cooperate with the company self-developed software can realize multi-channel signals at the same time of test, record, display, alarm and control output, and has USB interface, can be inserted U disk backup history data, or connect printer to print history curve and data.

8. Use frequency converter to adjust CO2 flow, which is convenient for process and energy saving.

FAQ

1. Q: What specifications do we offer?

A: We supply 0.5L~500ML machine for you, big capacity of machine also can be customized according to your requests.

2. Q: Does the CO2 can be reused?

A: YES. CO2 can be used in circulation.

3. Q: How long does it takes to produce the machine once place my order ?

A: Generally it takes about 60 workdays. We are responsible for the quality of machine our customers. Every procedure and detail has to be inspected strictly.

4. Q: How will my order be packed, can you provide the installation service?

A: Plywood case and wooden case. And we will assemble and test the machine before packing. If customer need, we will send one engineer for assembling and training for workers.

Deyang Sichuang Technology Co., Ltd.

- Phone: +86 838-13320855632

- Business Type: Trading Company

- Location: China

- Main Products: Supercritical CO2 Extraction Equipment,Screening and Crushing Plant,Pressure Vessel,Forging,Casting,Machinery Designing,Temperature and pressure test equipment,Reactor,Vacuum melting furnace polysilicon crystallization,Ultrasonic extraction equipment

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: