Our Company

Yunnan Zhongshi Engineering Technology Co., Ltd.

our company is engaged in the production of metallurgical machinery equipment, fluid components, fluid equipment, lubrication equipment, hydraulic cylinders, hose assemblies, metal hoses, flanges, elbows, various hydraulic accessories, valves and piping accessories. And selling professional companies.

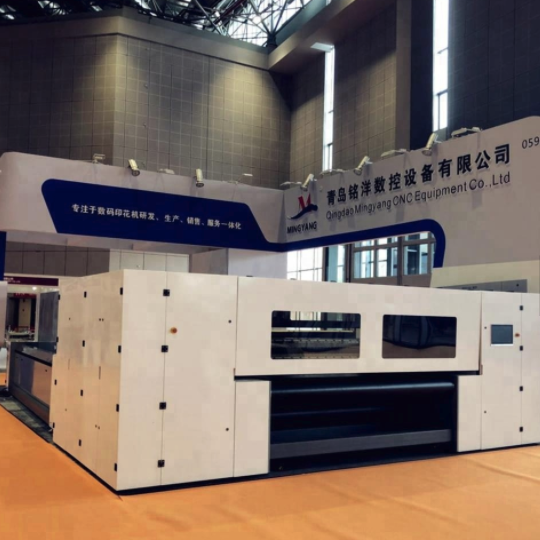

The company has more than 20 imported CNC equipments. All products have undergone rigorous tests through imported test benches. The products are processed by imported tools, and the finished products and equipment are exported to many countries in Europe and America. At the same time, our company is the agent of many world-renowned enterprises: The products are widely used, covering almost all walks of life, especially in metallurgy, machine tools, engineering vehicles, railway machinery, chemical, paper, shipbuilding and other industries. Our scope of supply mainly includes the following aspects: accumulators, fluid filtration equipment, hydraulic pumps, valves, cooling equipment, hydraulics, lubrication assemblies, hose assemblies, various pipe connections, hydraulic system accessories.

The purpose of the company is to survive by quality, develop by reputation, quality first, customer first, and sincerely provide quality products and services to customers. We sincerely hope to cooperate with new and old customers to create brilliance.

Product introduction

Technology development background

In the industrial and mining, municipal water supply, sewage treatment and industrial process cooling circulating water supply equipment, the past used is a multi-valve system consisting of check valves, globe valves, water hammer eliminators to meet the specific requirements of pump start and shutdown. In order to achieve light load start and eliminate water hammer. However, there are problems such as short service life, high resistance, high energy consumption, difficulty in manufacturing large diameters, large space occupation, and especially labor intensity. Later, with the development of science and technology, various pump control valves such as water pump control valves, multi-function water pump control valves, hydraulic control hemisphere butterfly valves, and pipe valves were gradually introduced. The emergence of these valves has promoted the development of pump control technology to a certain extent, but with the development of industry and the progress of the times, the defects of these water pump control valves are gradually revealed. If some valves require external energy, complicated structure, and difficult maintenance; some have large flow resistance coefficient and large volume, which is not conducive to the manufacture of large-diameter valves. The main problem is that the automatic control part is directly driven by the medium conveyed in the pipe. It is easy to make the control part block, corrosion causes control failure, maintenance is difficult, and the use range is narrow.

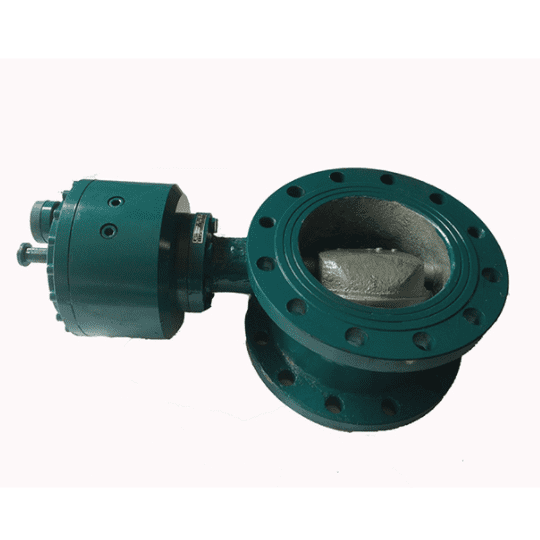

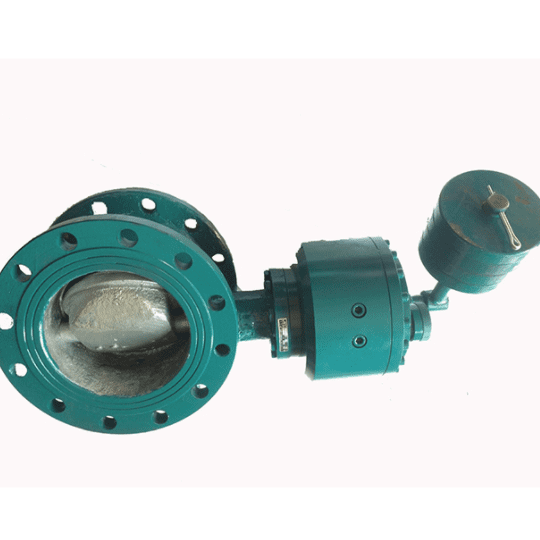

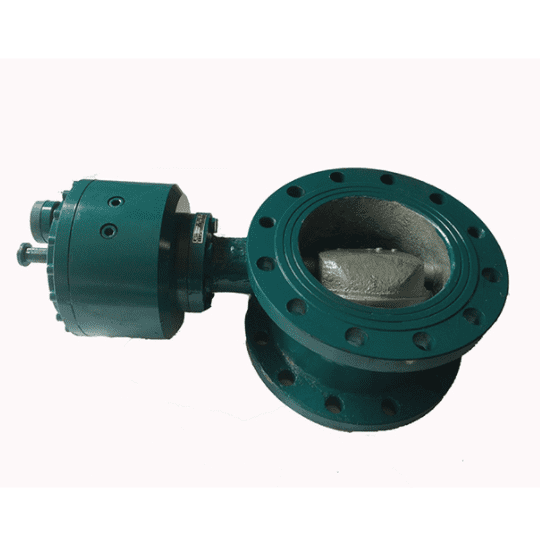

This product is a new series of pump control valve products. It fully utilizes the pressure energy of the pipeline itself to convert into hydraulic energy to realize the requirements of slow opening, quick opening, fast closing and slow closing of the control valve, which not only meets the automatic water pumping control. The requirements, in particular, overcome the problems of easy clogging in harsh working conditions such as slurry, sewage, mud, etc., and easy corrosion in corrosive media such as seawater, and overcome many shortcomings of the current pump outlet valve, and comply with the automatic and energy saving of the valve. Environmental development trend.

Product function use

The automatic double-controlled hemisphere valve is installed in the slurry pump, slurry pump, sewage pump, mud pump and clean water pump outlet. It is mainly used in electric power, metallurgy, mining, petrochemical, medicine, sewage treatment, seawater transportation, urban water supply and drainage and other industries. It not only eliminates water hammer, but also has low resistance, energy saving and low overall cost.

Main features

1. The fully automatic double-controlled hemisphere valve is the fifth generation of the latest pump control valve developed by our company. The control structure is the world's first. This product not only has all the functions of the first four generations of water pump control valves, but also expands the use range of the water pump control valve, overcoming the defects of the control valve that is not caused by the water quality problem, the diaphragm is easy to be damaged, and the piston cylinder is easy to be stuck. .

2. The valve slow-opening and slow-closing control device is independently controlled by the hydraulic controller, and there is no external bypass energy pipeline. The controller is hydraulic oil and has no connection with the medium in the pipeline. Therefore, the valve can be used for any working condition of the water pump outlet.

3. The power required to start and close the valve is taken from the pressure energy of the medium in the pipeline. The controller skillfully uses the pressure difference between the front and the rear of the valve. No external power source is required. When the pump is opened or stopped, the valve automatically moves according to the regular operation of the pump. Manual, electric, pneumatic and hydraulic external forces, do not manual operation, with automatic slow opening, quick opening, fast closing, slow closing effect, safe and reliable operation.

4. The flow area is large, the cross-sectional area of the valve plate is small, and the running resistance of the ordinary water pump control valve is 70% smaller, and the energy saving effect is obvious. The resistance coefficient of this valve is 0.2~0.5, and the magnitude of the drag coefficient is related to the energy consumption, which is also the operating cost that people often say.

5. The sealing surface of the valve body is a conical surface, and the sealing surface of the valve plate is a spherical surface. The sealing surface material is stainless steel or cemented carbide. The sealing surface is hard-sealed, and the sealing property is a wire seal. Therefore, the sealing surface has a small overlapping area, and the sealing ratio is large, which is a true zero-hard, hard-hard metal hard seal. The valve plate can cut, crush, and discharge various filamentous, granular suspension and semi-suspended impurities. It can effectively crush and remove scale. Because the product adopts three eccentric structure, the spherical valve plate can automatically align the center and automatically compensate the wear of various sealing surfaces, so the service life of the valve is much longer than similar products.

6. This product is not affected by the medium. It can be used in complex working conditions such as clean water pump, slurry pump, sewage pump and mud pump. It is also suitable for corrosive media such as sea water.

Technical Parameters

Nominal diameter: DN80-4000mm Nominal pressure: 0.6, 1.0, 1.6, 2.5, 4.0, 6.3Mpa

Minimum operating pressure: 0.05MPa Applicable temperature: -10~200°C

Applicable medium: sewage, mud, pulp, slurry, water, oil, seawater, chemical fluid, etc.

Resistance coefficient: ≤0.2~0.5 Sealing performance: working pressure 1.1 times, duration 15S

Leakage: ≤0.01XDN (GB/T3927-92B)

Water hammer peak: 1.3 times pump working pressure Slow opening, slow closing time: 1~60S adjustment

Component material

Body: carbon steel, stainless steel Controller: carbon steel, ductile iron

Valve plate: carbon steel, stainless steel valve stem: stainless steel

Sealing surface: alloy steel, hard alloy, stainless steel

O-ring: NBR, fluoro rubber

Yunnan Zhongshi Engineering Technology Co., Ltd.

- Phone: +86 871-13882365180

- Business Type: Trading Company

- Location: China

- Main Products: Hydraulic system,The hydraulic oil cylinder,Hydraulic pipe fittings,Mechanical parts,Valve accessories

- Total Employees:100-500 people

- Year Established:

- Export Markets:

- Total Annual Revenue: