§ Equipment application

1.The copper rod continuous casting and rolling line can be equipped with different kinds of melting furnaces according to various raw materials (copper cathode or copper scrap of above 94% Cu content).

2.The copper rod continuous casting and rolling machine can produce ETP and FRHC with dia. 8mm.

3.The copper rod continuous casting and rolling machine is designed to produce φ8mm low oxygen and bright copper rods by means of continuous casting and rolling.

§ Equipment feature

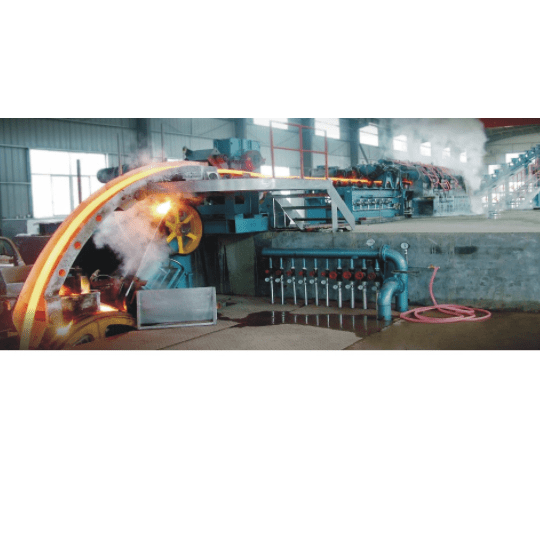

1. Crystallizing wheel is in type of “H”, on every side of which there is an adjustable nozzle spraying water to ensure the crystal of the cast bar close and equal.

2. The copper rod continuous casting and rolling machine is with an unique rolling method combining 2-high mould with 3-high mould.

3. The copper rod continuous casting and rolling machine is with perfect outlook & lower noise and vibration.

4. The transmission system is in type of DC motor fully-digital speed adjusting.

5. High efficiency & quality of production, low dissipation energy.

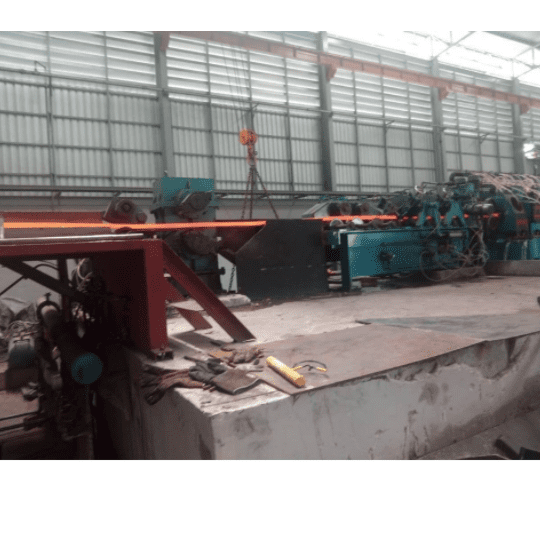

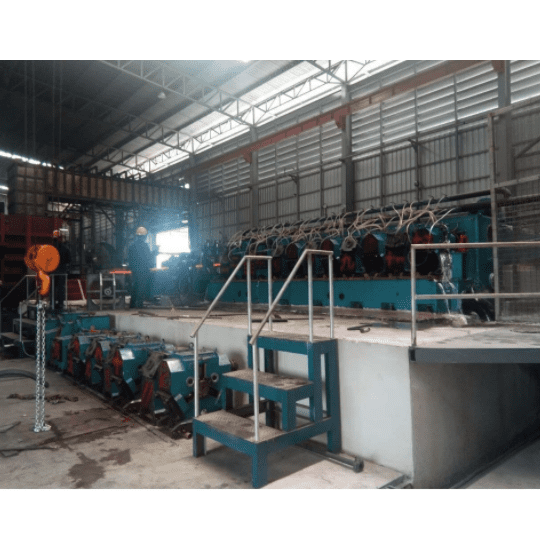

§ Equipment composition

The copper rod continuous casting and rolling line is mainly made up by reverberatory furnace or tilting type furnace (when copper scraps above 94% are as the raw materials), shaft furnace and holding furnace are provided when copper cathode are used, 5-wheel casting machine, traction engine, scrolling shear, ingot picker, oil hydraulic shear, straightener and edge shaver, cast bar brushing machine, rolling mill, Rod cooling and surface treatment unit, take-up device electric control system,etc.

§ Technical Data

Melting furnace & Holding Furnace,copper cathode as raw material | Melting furnace type | Shaft furnace |

Capacity | 12t | |

Holding furnace type | Hydraulic tilting-type | |

Capacity | 12t | |

Melting furnace, copper scraps are used | Type | Reverberating furnace or tilting furnace |

Capacity | 20~100t | |

Casting Machine | Casting wheel diameter | Φ1800mm |

Casting bar speed | 10.1~15.5m/min | |

Casting bar section | 2350mm² | |

Water consumption | 170m³/h | |

Motor for casting wheel | 5.5kW(AC inverter) | |

Motor for pinch roller | 15.5kW(AC inverter) | |

Automatic Shearer | Shearing length | ~700mm |

Motor | 15kW | |

Straightener & edge shaver | No. of straightening roller | 5 |

No. of shaving tools | 2 | |

Cast bar brushing machine | No. of brushing rollers | 1 |

Motor | 0.75kW | |

Continuous rolling mill | Type | 2-highhorizontal-vertical stand in rough rolling |

3-high stand in finished rolling | ||

Outlet rod dia. | Φ8mm | |

No. of rolling stand | 12(4+8) | |

Rollers dia. | Φ255mm | |

Finished rolling speed | 7~10m/s | |

Production capacity | 12~15t/h | |

Center height | 1902.5mm | |

Main motor | 450kW (DC) | |

Emulsion consumption | 100m³/h | |

Rod cooling and surface treatment unit | Max. coolant flow-rate | 90m³/h |

Coolant pump motor | 15kW | |

Water consumption | 60m³/h | |

Option 1: Rod orbital coiler | Pulling speed | 11m/s |

Pulling motor | 5.5kW (AC inverter) | |

Coiling size | Φ1400m | |

Laying head motor | 5.5kW (AC inverter) | |

Collecting basket | Φ1800×1500mm | |

Coiling weight | 3000~5000kg | |

Option 2: Hydraulic pressure rod coiler | Coiling method | Hydraulic pressure coiling |

Coiling weight | 4T (It can be displayed) | |

Coiling outside diameter | ø1500mm-ø1800mm | |

Coiling inside diameter | ø800mm | |

Travelling roller table | Motor power 4KW | |

Main motor power | 22KW |

In China, we are a state-owned factory. We can assure that it is the best one. We having the advanced design concept and manufacture technology, our products are stable and reliable. We can undertake manufacturing all kinds of complete equipments of Melting Furnace Series, Copper, Aluminum & Alloy Rod Continuous Casting and Rolling Line Series, Aluminum Strip Continuous Casting and Rolling Line Series, Wire Drawing Machine Series, etc. As a result of high quality products and outstanding customer service, we have gained a global sales network reaching Pakistan, Iran, Thailand, Malaysia, Belarus, Ukraine, Syria, etc. And our rod ccms have more than 70% market share in Chinese market. Our general engineer is the person who participatory designed the first line of melting furnace & copper rod continuous casting and rolling line in China.