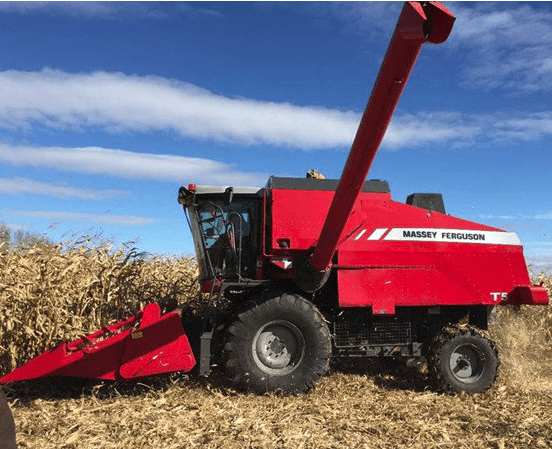

Massey Ferguson's existing combine harvester series can fully meet the harvesting needs of all agricultural scales. ACTIVA, BETA, CENTORA, FORTIA and DELTA harvesters have a variety of sizes and functions to achieve a real sense of high yield and reliability.

Innovation has always been respected in the design and production of Merseyside Ferguson Harvester, enabling it to take the lead in cutting, threshing, separation, removal and transportation technology for a long time. For 30 years, Massey Ferguson has been pursuing progress and originality, and has achieved many milestones, such as PowerFlow table and rotary separation harvester, which are still in the leading position in the field of harvesters.

MF DELTA combine harvester (combined with the great advantages of traditional screw technology) has entered the market, representing a major step forward in the supply of Mercedes Ferguson harvesting products. MF DELTA is the first harvester in the world to adopt the technology of IKESAI engine and selective catalytic reduction (SCR). At the same time, the MF FORTIA rotary harvester manufactured by Huston Production Base is very popular and has good performance, which has played a huge role in promoting agricultural development.

The most important thing is that even at the busiest time of the year, users can get all-weather support from the Massey Ferguson technology team.